Grinding and dispersion technology

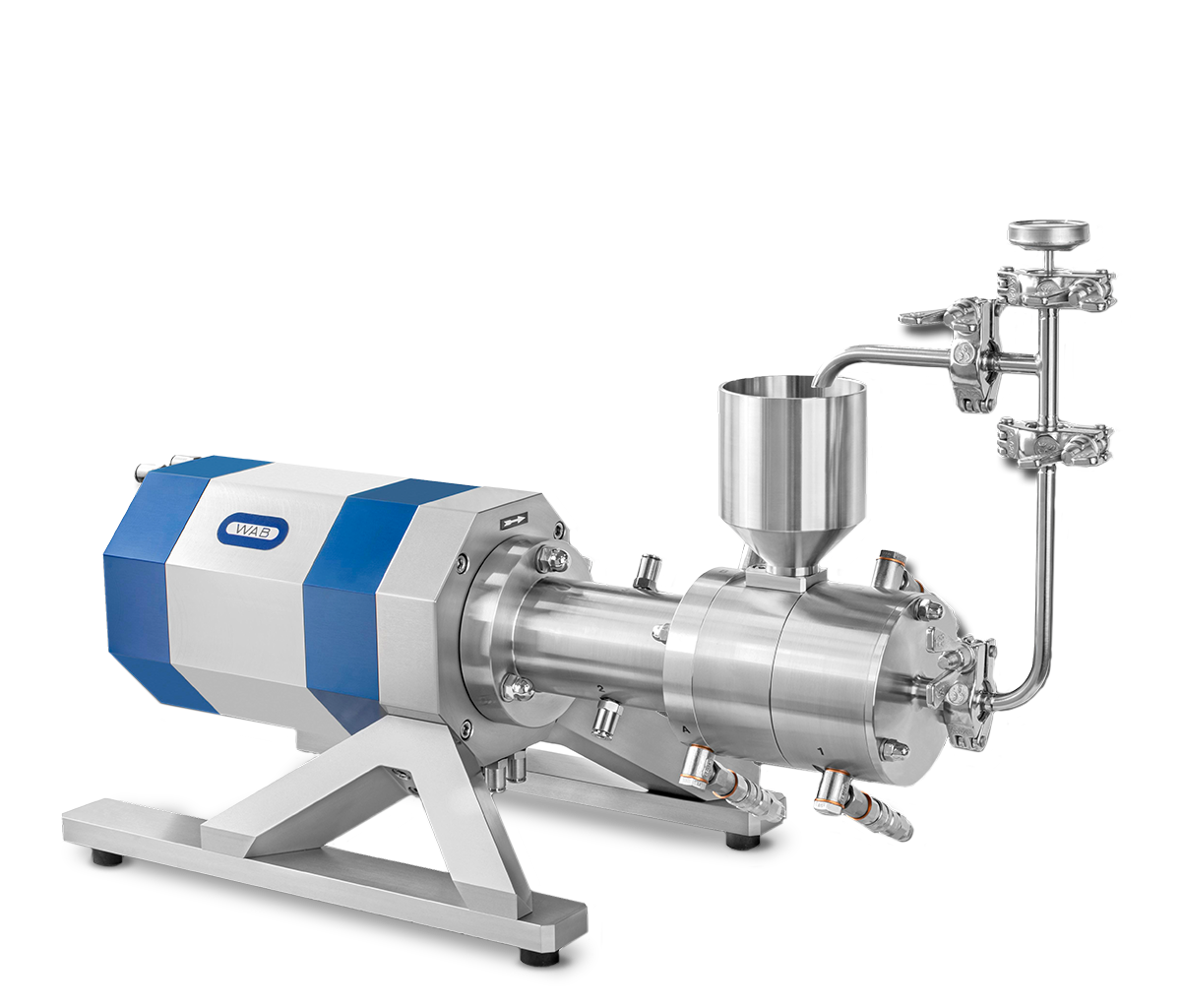

High-Performance Agitator Bead Mill

DYNO-MILL ECM-AP

The ideal agitator bead mill for high throughputs and highly viscous products

Industries

Evolution in high-performance agitator bead mill design

The innovative DYNO-MILL ECM-AP series is designed to increase throughputs.

With a high grinding efficiency, the finest and narrowest particle distributions down to the nanometer range are produced. The patented separation system with self-cleaning effect improves the driveability of highly viscous products. Screen blockages can be avoided and production interruptions for screen cleaning become rare - a considerable advantage depending on the product.

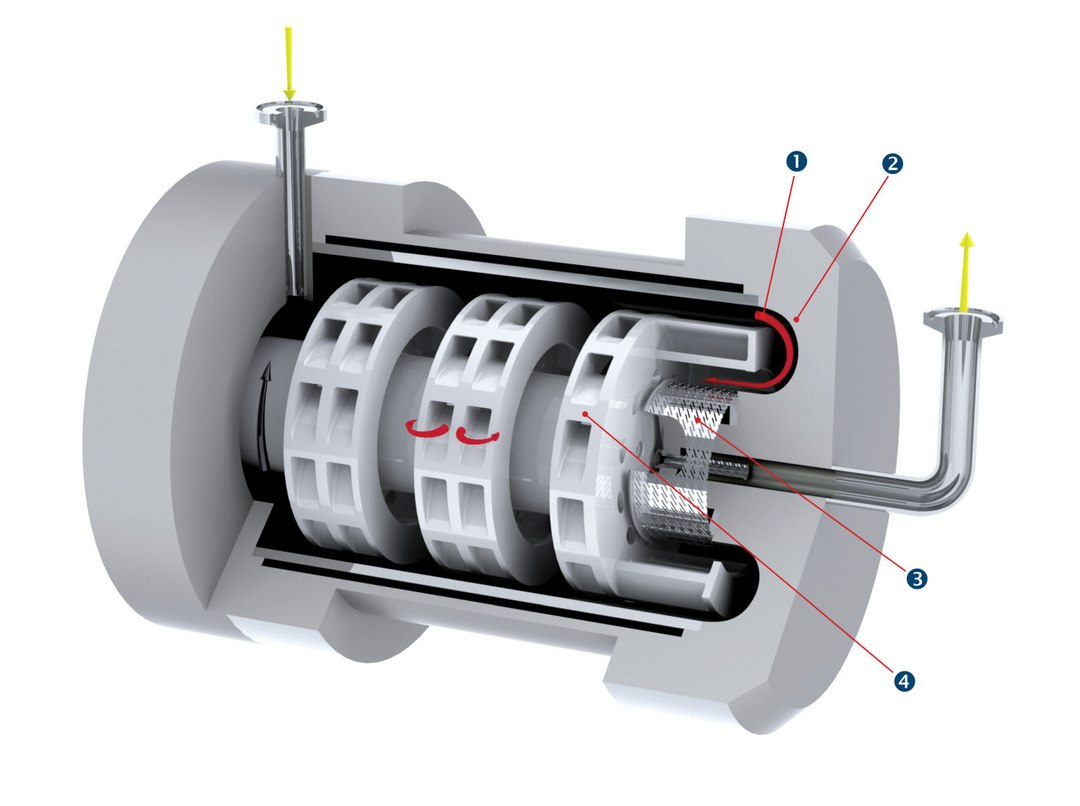

Functionality

The grinding media separation system is characterized by a flow-optimized and guided grinding media circuit. The grinding media are guided axially over the screen surface by the deflection ring. Subsequently, the DYNO-ACCELERATOR DSE conveys the grinding media back to the deflection ring without tearing them off.

The axial guidance of the grinding media over the screen surface helps to remove coarser particles from the cross sections through which they flow and is the basis for the unique self-cleaning effect of the DYNO-MILL ECM-AP separation system.

Separation system with self-cleaning effect

- Grinding bead circulation

- Deflection ring

- Screen surface

- DYNO-ACCELERATOR DSE for powerful and efficient wet grinding

Features

- Suitability for high throughputs and highly viscous products

- Greater flexibility in the selection of process parameters

- Availability of metallic and ceramic variants

- Uniform grinding media density distribution in the grinding chamber for maximum efficiency

- Efficient grinding with grinding media from ø 0.1 mm

- Low energy consumption thanks to hydraulic grinding media acceleration

- Holistically optimized flow guidance for optimum particle residence time distribution

- Suitability for the production of all types of nano-suspensions

- Suitability for passage and circuit mode

- Venting of the grinding chamber through patented venting system

- Long screen life

- Simple and ergonomic machine handling for the fastest product changes

- Minimal costs for cleaning agents when changing products

- Grinding of temperature-sensitive products thanks to very effective cooling of the grinding chamber

- Easy operation of the mill thanks to well thought-out control concept

- Low noise level

- Wide range of control solutions

Customized solutions

Our experience helps us to meet your process needs for projects with different and special requirements and to offer you a customized solution, such as the agitator bead mill DYNO-MILL Pharma.

Download

Find more information on our high-performance agitator bead mill in compact form as a PDF file. New grinding at the highest level.

Technical specifications

| Type | ECM-AP 05 | ECM-AP 2 | ECM-AP 10 | ECM-AP 20 | ECM-AP 60 |

|---|---|---|---|---|---|

| Grinding container volume (L) | 0.5 | 1.9 | 9 | 21 | 62 |

| Mill drive (kW) | 4 | 11 | 30-37 | 44-58 | 100-132 |

| Cooling water throughput (L/h) | 250-400 | 1000-1500 | 1500-2200 | 1800-2500 | 3000-4000 |

| Weight (kg) | 120-140 | 500-600 | 1100-1200 | 1750-1900 | 4100-4300 |

| Dimension L x W x H (mm) | 825 x 625 x 725 | 1150 x 760 x 1590 | 1520 x 900 x 1860 | 1970 x 1090 x 2090 | 2330 x 1340 x 2220 |

YOUR RELIABLE PARTNER

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.