Mixing Technology

3D Shaker Mixer

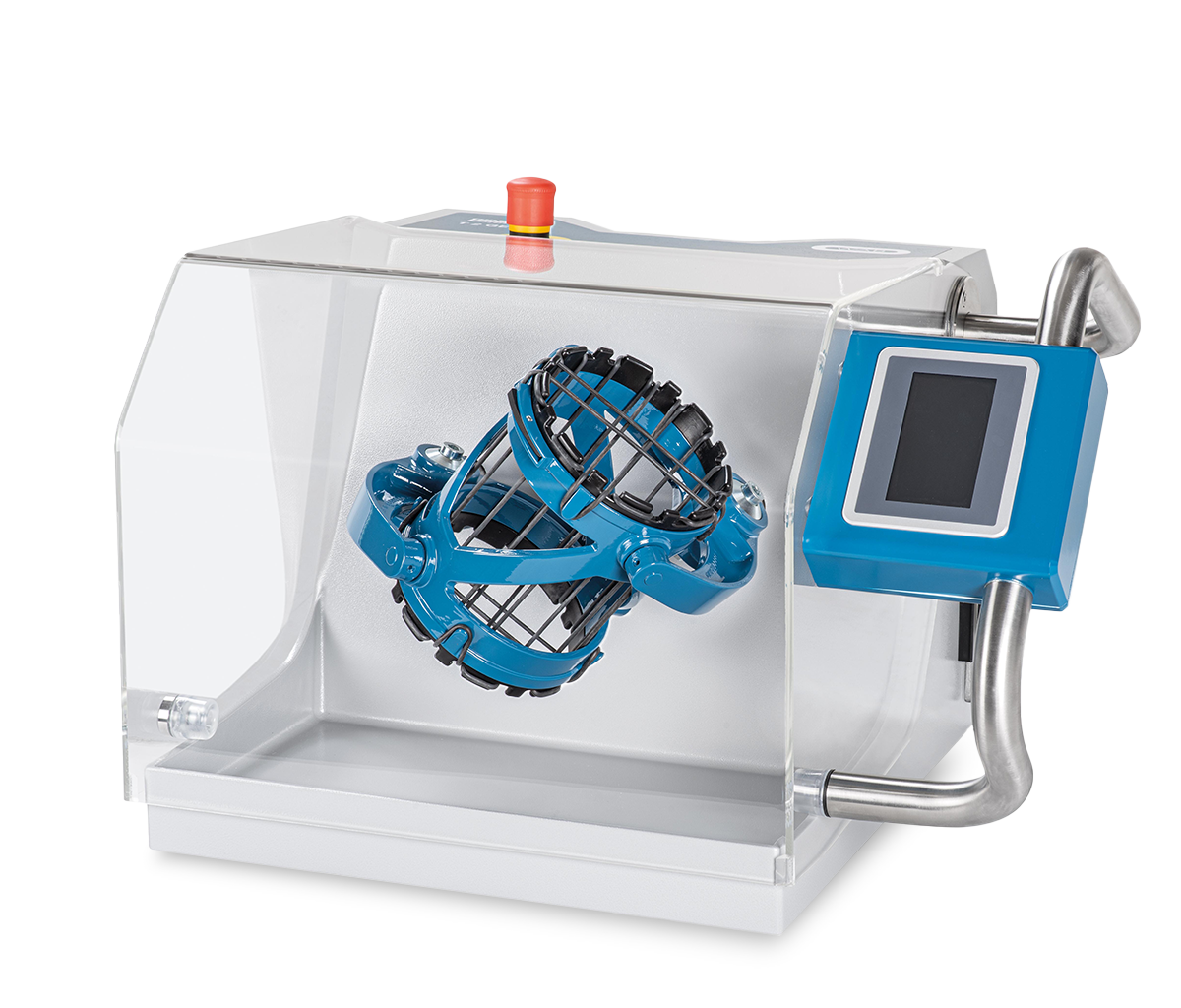

TURBULA

3D shaker mixer for container volumes from 0.1-55 liters

Industries

Reliable partner for your processes

With the TURBULA series you can produce compounds with the highest quality requirements and excellent reproducibility.

The high mixing efficiency of these 3D shaker mixers results in the shortest mixing times and thus an extremely gentle mixing process. The mixers are easy to operate and enable hygienic work. You are flexible in your choice of mixing containers. These advantages make the TURBULA a popular 3D shaker mixer in laboratory and production.

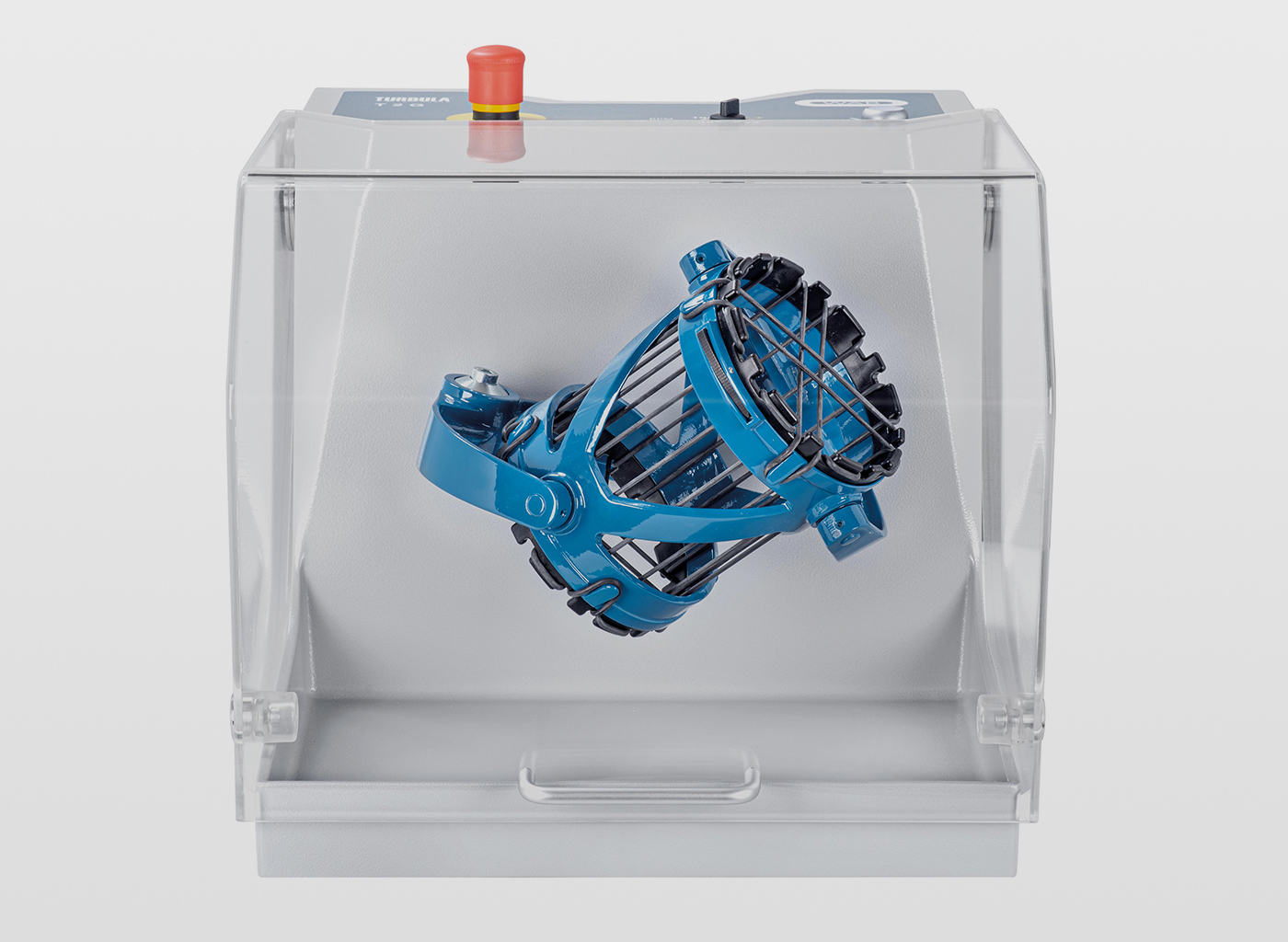

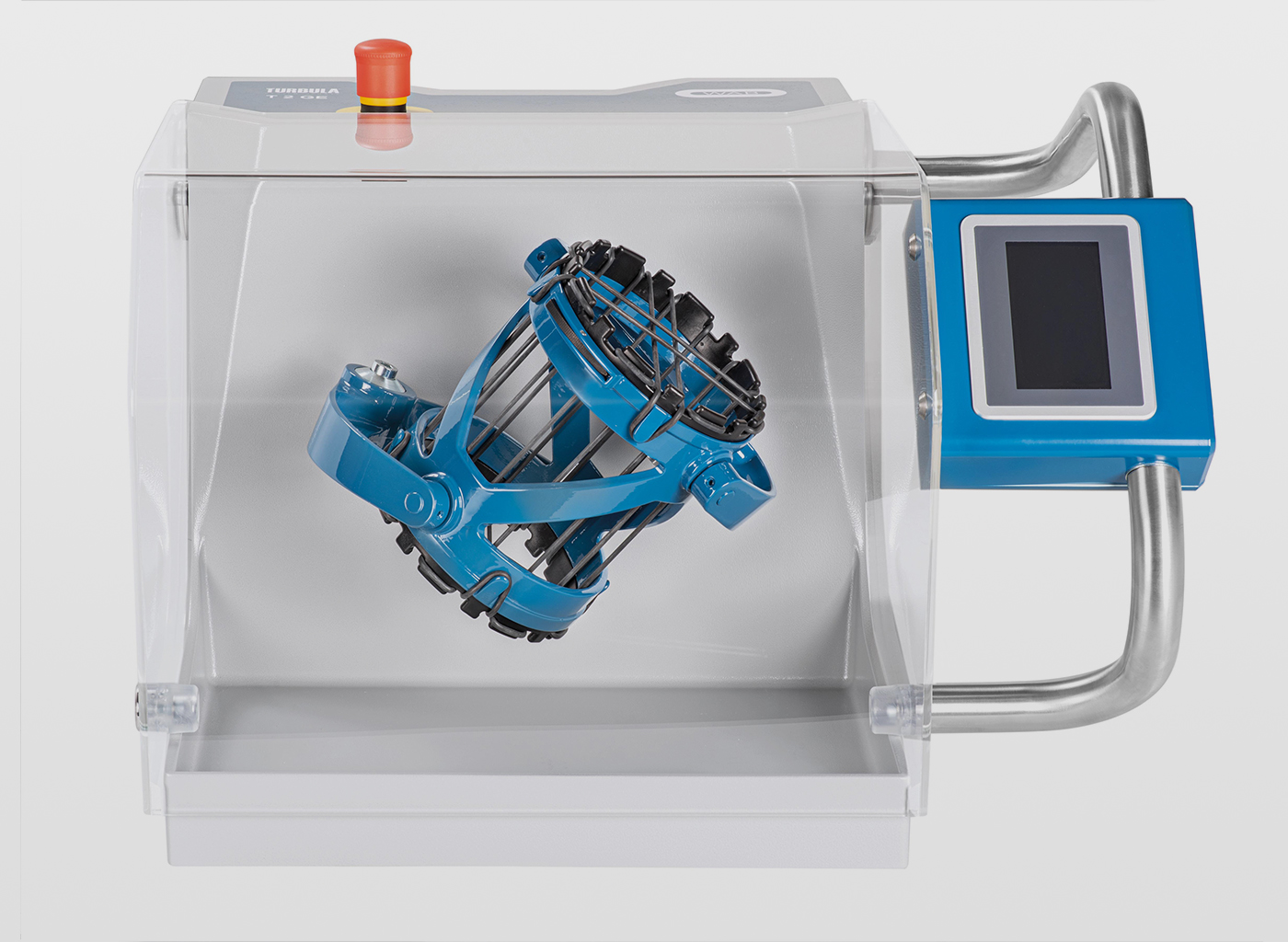

Functionality

The extraordinary efficiency of the TURBULA mixers is based on the interaction of rotation, translation and inversion during the mixing process. The mixing container is set into a three-dimensional motion. The mixed material is put into a constantly changing and rhythmically pulsating state. In the shortest possible time, high-quality mixing results are achieved that meet the highest requirements.

T 2 G

- EMERGENCY STOP button

- Selector switch

- Start/stop function

- Protective cover

- Handle

- Machine housing

- Clamping wrench

T 2 GE

- Start/stop function

- Intuitive touchscreen

- Recipe management (up to 20 recipes)

- Timer function

- PLC based control

- Infinitely variable speed regulation: 23 to 101 1/min

- Password protected operation

Features TURBULA

The TURBULA mixers are used to produce homogeneous mixtures of powdery components with different specific weights and particle sizes. Dry-liquid and liquid-liquid mixtures are also possible. The mixing process takes place in a completely closed vessel and is therefore contamination-free. The TURBULA mixers can use containers of different sizes and shapes.

- Simple operation and maximum reproducibility

- Easy cleaning

- No segregation

- Easily accessible container holder for quick container changes

Features T 30 A

The mixing basket is designed to hold standard mixing containers with a volume of up to 30 liters. Inserts for smaller container sizes are available. The synchronization of the mixing movement (every 4 ms) ensures a uniform energy input. The speed can be continuously adjusted and user-specific mixing recipes can be saved via the intuitive touchscreen on the control panel. If required, a table can also be ordered. This ensures optimum working height, stability and flexibility.

Features T 50 A

The mixing basket is designed to hold standard mixing containers with a volume of up to 55 liters. Appropriate inserts must be provided for smaller containers. The mixing basket is driven and its movement controlled by a low-noise pendulum chain drive. The speed is set by engaging the drive V-belt on the 5-stage pulleys. The mixing basket is brought into the loading position by means of a creep drive. A hand trolley is optionally available for loading. TURBULA T 50 A is preferably used in the pharmaceutical industry and for mixing sintered metals, ceramic materials and sensitive products.

Customized solutions

For use in the cosmetics, pharmaceutical and food industries, our TURBULA mixers are available in different versions on request.

Examples of different designs

- Suitable for installation in insulators

- Hermetically sealed machine housing with ventilation system

- Available completely in stainless steel or with a food-safe paint finish

- Stainless steel table

Download

Find more information about our 3D shaker mixers in compact form as PDF file. High reproducibility and exceptional homogeneity.

Technical specifications

| Type | T 2 G | T 2 GE | T 30 A | T 50 A |

|---|---|---|---|---|

| Engine (kw) | 0.55 | 0.55 | 0.75 | 1.1 |

| Connection (V, Hz) | AC 100-127, 50/60 AC 208-240, 50/60 | AC 100-127, 50/60 AC 208-240, 50/60 | AC 100-127, 50/60 AC 208-240, 50/60 | 3 x 220-420, 50/60 |

| Speed (rpm) With frequency converter | 23/34/49/72/101 | 23-101 | 44 | 16/20/25/32/40 16-40 |

| Standard container dimension (mm / L) | Ø 130 x 215, max. 2 | Ø 130 x 215, max. 2 | Ø 315 x 416, max. 30 | Ø 360 x 560, max. 55 |

| Container sizes with rubber clamping rings (mm) | max. Ø 130 x 215 | max. Ø 130 x 215 | - | - |

| Max. load incl. container (kg) | 6 (23-101 min-1) 10 (23-72 min-1) | 6 (23-101 min-1) 10 (23-72 min-1) | 40 | 50 (32-40 min-1) 75 (16-25 min-1) |

| Machine weight (kg) | 58 | 58 | approx. 180 | 800 |

| Dimension L x W x H (mm) Closed, Open | 620 x 470 x 450 620 x 470 x 758 | 625 x 620 x 450 625 x 620 x 758 | 1000 x 1090 x 760 1111 x 1090 x 1140 | 1386 x 1336 x 1025 1563 x 1556 x 1608 |

We are here for you

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.